Heatsinks Without Fins (Dummy Loads)

Specific Heat

All materials have a property called specific heat which describes how much the material temperature rises when a given amount of energy is applied to the material. The specific heat value assumes the energy is applied uniformly and that there is no loss due to convection etc. Thermal conductivity is the property more commonly seen when discussing heatsinks and describes how well the heat spreads.

Material Specific heat Density Thermal Conductivity

Aluminum .902 J/g°C 2.74 g/cm3 250 W/m°C

Copper .385 J/g°C 8.93 g/cm3 401 W/m°C

Water 4.180 J/g°C 1.00 g/cm3 0.58 W/m°C

Air 1.01 J/g°C .0012 g/cm3 .024 W/m°C

Oil 1.65-1.97 J/g°C .8-.92 g/cm3 ??

Alcohol 2.3-2.5 J/g°C .78-1.12 g/cm3 ??

In the above table, J = joules = W * s (watt seconds), g = grams, °C = degrees C, cm3 = cubic centimeters, W = watts, and m = meters. For aluminum .902 J/g°C means that .902 watt seconds of energy raises the temperature of 1 gram of aluminum 1 °C.

It started with an attenuator

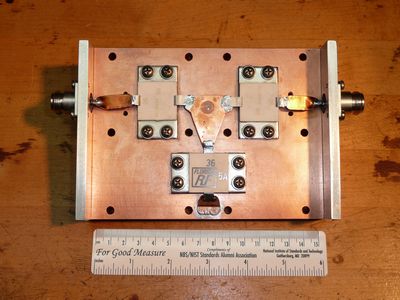

I needed a high power attenuator with about 10dB. of attenuation for some measurements I was making. Most high power attenuators are usually 30dB or 40dB. which are much more useful for driving test equipment and high power 10dB attenuators are hard to find. However I had several high power (800W) resistors in my junk box from previous jobs and happened to find some that were nearly perfect for the needed high power attenuator. The photo shows the "Tee" attenuator with the series resistors of 25 ohms and the shunt resistor of 36 ohms.

With 1500W applied, the input series resistor dissipates 758W, the shunt resistor dissipates 500W, and the output series resistor dissipates 80W. The load receives 160W resulting in a 9.7dB attenuation and the input SWR was less than 1.05:1 thru 60MHz. The resistors were mounted on a large copper block measuring 6.0"x4.5"x0.75" and was drilled to mount to a larger finned heatsink. However before mounting to the finned heatsink I decided to do a quick test and was surprised how little the temperature of the copper rose. The resistors are rated for full power with a flange temperature of 100 °C. Applying 1500W to the attenuator for 60 seconds caused the temperature of the copper to rise from 20 °C to 89 °C. I didn't even need the finned heatsink for my tests. Good news is always nice but this warranted a closer look.

Analysis of my attenuator

The 6.0"x4.5"x0.75" copper block is 20.25 in3 or 331.8 cm3 with a mass of 2963g (~6.5 lb.). 1500W input causes the attenuator to dissipate 1340W (160W goes to the load). Doing the calculation with the RF applied for 60 sec., temp rise = {(1340*60)J/(2963g)}*1/(.385J/g°C) = 70.5 °C. This would predict a final copper temperature of 90.5 °C which is quite close to my measured 89 °C. The difference is most likely due to some convection from the copper. The problem with building projects using large copper blocks is the price of copper. I currently pay ~$3.80/lb. for copper like this piece and about $1.00/lb. for 2024/6061/7075 aluminum blocks from my scrap metal dealer. The copper block I used for this project cost ~$25.00.

What about something less expensive?

What if the 6.0"x4.5"x0.75" copper block was replaced with an aluminum one. How much higher would the temperature rise be for aluminum? The aluminum block would still be 331.8 cm3 but the mass would now drop to 909 g (2.0 lb.). Doing the same calculation now results in a temperature rise of (1340*60)/(909*.902) = 98 °C. This is more than the copper but NOT that much more. How much different would the temperature rise be between a 6.5 lb. copper block and a 6.5 lb. aluminum block. The actual dimensions aren't important but I will assume the entire block has the same temperature rise. Doing the calculation shows a temperature rise of (1340*60)/(2963*.902) = 30 °C. This is perfect! Now a less than $7.00 chunk of aluminum will allow my attenuator to be driven with 1500W for over 2 minutes and still only be at 80 °C. This is less expensive than a reasonable sized extruded finned heatsink but it is heavier. For aluminum, 2963 g is a volume of 1081 cm3 or 66.0 in3. An aluminum block 6"x6"x2" is a volume of 72 in3. If you can't find a scrap dealer, a block this size can be purchased from online metal dealers for ~$36. For long duty cycle use the big aluminum block can be immersed in 1 inch of water in a shallow container. 1500W raises 1 gallon of water 5.7 °C per minute.

Heathkit Cantenna of MFJ-250 dummy loads

Many of us have had one of the 1 gallon oil filled paint can dummy loads and they are still popular. MFJ sells the MFJ-250 for $80 including oil. The ones I had always were weeping an oil mist and I never really liked that. A couple 100 ohm 800W resistors (~$40 ea.) in parallel and a $7 chunk of aluminum might be more to your liking.

Many of us have had one of the 1 gallon oil filled paint can dummy loads and they are still popular. MFJ sells the MFJ-250 for $80 including oil. The ones I had always were weeping an oil mist and I never really liked that. A couple 100 ohm 800W resistors (~$40 ea.) in parallel and a $7 chunk of aluminum might be more to your liking.

Page content last updated Jul. 9, 2012

Copyright © 2012 Larry Benko, W0QE

Finned heatsink and solid block differences

I do not mean to imply that a heatsink made from a solid block is better than a conventional finned heatsink. For heatsinks occupying similar volumes and having similar temperature rises the following comparisons can be made.

Solid block heatsink:

Absorbs more energy but gives up the energy more slowly and obviously weighs more.

Finned heatsink:

Absorbs less energy but gives up the energy more quickly (especially with forced air flow) and weighs less.

Generally a dummy load is used in a high power low duty cycle mode and is well suited to a solid block heatsink.

I do not mean to imply that a heatsink made from a solid block is better than a conventional finned heatsink. For heatsinks occupying similar volumes and having similar temperature rises the following comparisons can be made.

Solid block heatsink:

Absorbs more energy but gives up the energy more slowly and obviously weighs more.

Finned heatsink:

Absorbs less energy but gives up the energy more quickly (especially with forced air flow) and weighs less.

Generally a dummy load is used in a high power low duty cycle mode and is well suited to a solid block heatsink.